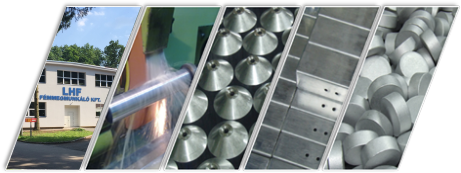

Deep Drawing

The shape of the deep drawn components are usually hollow parts - which can be removed from the tools – the bottom of the produced components can be flat or shaped, the wall thickness is usually the same as the bottom thickness. The raw materials of the deep drawn components are usually steel, aluminium and copper.

The deep drawing technology offers in many cases a more cost-effective solution of producing steel, aluminium and copper hollow components comparing to other technologies, the investment in the tooling might return even at a relatively small (5 000 pieces) volumes.

Deep drawing is a sheet metal forming consists of the transformation, by cold forming, of a raw material sheet or strip into a product by application of one or more relatively high force impact applied by a special type of mechanical or hydraulic press. Depending on the geometry of the product the deep drawing process might be called simple deep drawing or require forward or backward flow of the material or a combination of both of these modes. With further operations additional features can be formed on the component such as holes, grooves, threads.

Advantages particularly associated with the deep drawing process:

- Steel, stainless steel, copper and aluminium components can be produced

- Economy of manufacture achieved through minimum material and energy usage

- Rapid production rate

- Thin wall hollow components can be produced

- Maintenance of fine tolerances over an extended production run

- Fine surface finish immediately suitable for most surface treatments

Machines of the deep drawing technology

Generally used machine for the deep drawing are the hydraulic and eccentric presses. The capacities of our presses are vary between 5 to 250 tons. Hydraulic presses are existing with capacity of 3 000 tons.